Hydraulic Pumping System Analysis

Context: Pressurized Pipe FlowThe study of a fluid (like water) moving through closed conduits (pipes) under pressure, where the flow is driven by a pump or gravity..

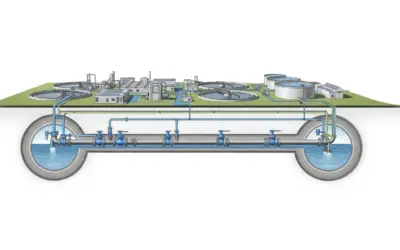

This exercise involves a common civil engineering problem: selecting a pump to move water between two reservoirs at different elevations. We need to transport 500 Gallons Per Minute (GPM) of water from a lower reservoir (A) to an upper reservoir (B). To do this, we must determine the total resistance of the piping system and calculate the total energy, or head, that the pump must provide. Finally, we will determine the power required to run the pump.

Pedagogical Note: This exercise will teach you to apply the general energy equation to a real-world pumping system. You will learn to identify and calculate all components of the "system head": the static lift (elevation change), the major head losses (from pipe friction), and the minor head losses (from fittings and valves).

Learning Objectives

- Apply the general energy equation to a system with a pump.

- Convert flow rate (GPM) to fluid velocity (ft/s) using US Customary Units.

- Determine major head loss (friction loss) using the Darcy-Weisbach equation.

- Calculate total minor head loss from component K-factors.

- Determine the total required pump head (System Head, \(H_p\)) and the required Brake Horsepower (BHP).

Study Data

System Specifications

| Characteristic | Value |

|---|---|

| Reservoir A Water Elevation (Suction) | 100 ft |

| Reservoir B Water Elevation (Discharge) | 220 ft |

| Required Flow Rate (\(Q\)) | 500 GPM |

| Pipe Material | Ductile Iron |

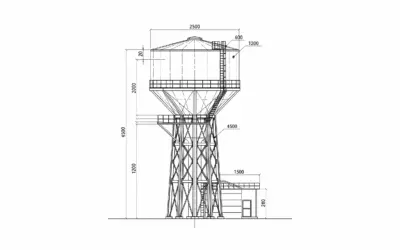

Pumping System Schematic

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Pipe Length | \(L\) | 800 | ft |

| Pipe Diameter | \(D\) | 6 | in |

| Darcy Friction Factor | \(f\) | 0.020 | - |

| Minor Loss, Entrance (sharp) | \(K_{\text{ent}}\) | 0.5 | - |

| Minor Loss, 2x 90° Elbows (total) | \(\Sigma K_{\text{elb}}\) | 0.6 | - |

| Minor Loss, Check Valve | \(K_{\text{val}}\) | 2.0 | - |

| Minor Loss, Exit (submerged) | \(K_{\text{exit}}\) | 1.0 | - |

| Pump Efficiency | \(\eta\) | 75 | % |

| Acceleration of Gravity | \(g\) | 32.2 | ft/s² |

Questions to Address

- Calculate the flow velocity (\(V\)) in the pipe (in ft/s).

- Calculate the major (friction) head loss (\(h_f\)).

- Calculate the total minor head loss (\(h_m\)).

- Calculate the total system head (required pump head, \(H_p\)).

- Calculate the required Brake Horsepower (BHP) for the pump.

Fundamentals of Pressurized Flow

To solve this problem, we apply the general energy equation between the surface of Reservoir A (point A) and Reservoir B (point B).

1. The Energy Equation

The energy equation for a system with a pump is:

\[ \frac{p_A}{\gamma} + z_A + \frac{V_A^2}{2g} + H_p = \frac{p_B}{\gamma} + z_B + \frac{V_B^2}{2g} + h_{L, \text{total}} \]

Since both reservoirs are open to the atmosphere, \(p_A = p_B = 0\) (gage). Since they are large, we assume \(V_A \approx V_B \approx 0\). The equation simplifies to:

\[ H_p = (z_B - z_A) + h_{L, \text{total}} \]

This means the Pump Head (\(H_p\)) must overcome the Static Head (\(z_B - z_A\)) plus the Total Head Loss (\(h_{L, \text{total}}\)).

2. Total Head Loss (\(h_{L, \text{total}}\))

Total head loss is the sum of major (friction) losses and minor (component) losses:

\[ h_{L, \text{total}} = h_f + h_m \]

We use the Darcy-Weisbach equation for friction loss and the K-Factor method for minor losses. Both depend on the velocity head, \(\frac{V^2}{2g}\).

\[ h_f = f \frac{L}{D} \frac{V^2}{2g} \quad \text{and} \quad h_m = (\Sigma K) \frac{V^2}{2g} \]

Solution: Hydraulic Pumping System Analysis

Question 1: Calculate the flow velocity (\(V\)) in the pipe (in ft/s).

Principle

To find velocity, we use the continuity equation \(V = Q/A\). We must first convert the flow rate \(Q\) from Gallons Per Minute (GPM) to cubic feet per second (ft³/s or cfs) and the pipe diameter \(D\) from inches to feet to calculate the area \(A\).

Mini-Lesson

Key Conversions (US Customary):

- The flow rate \(Q\) is a *volume* per *time*. We need to work in standard units of ft³/s (cfs).

- 1 ft = 12 in

- 1 GPM \(\approx\) 0.002228 ft³/s

- Area of a circle: \(A = \frac{\pi D^2}{4}\)

Pedagogical Note

This first step is the most critical. A simple error in unit conversion (like forgetting to square the \(1/12\) conversion for diameter) will make every single subsequent calculation incorrect. Always convert all inputs to base units (feet, seconds) *before* calculating.

Norms

The conversion factor for GPM to cfs (0.002228) is a standard value used extensively in American fluid mechanics and is derived from the volume of a US gallon (231 cubic inches).

Formula(s)

Pipe Area

Velocity

Hypotheses

We assume the pipe has a constant diameter of 6 inches and the flow is steady. We also assume the pipe is flowing full.

Data

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Flow Rate | \(Q\) | 500 | GPM |

| Pipe Diameter | \(D\) | 6 | in |

Tips

A quick check: A 6-inch pipe is 0.5 ft. The area \(A\) is about 0.2 ft². A flow of 1 cfs in this pipe would give a velocity of \(1 / 0.2 = 5\) ft/s. Our flow is \(\approx 1.1\) cfs, so our answer should be slightly more than 5 ft/s. This confirms 5.68 ft/s is reasonable.

Schematic (Before Calculations)

Pipe Cross-Section

Calculation(s)

Step 1: Convert Units

First, we convert the diameter from inches to feet and the flow rate from GPM to cubic feet per second (cfs).

We will use these converted values (\(D = 0.5\) ft and \(Q = 1.114\) cfs) for all future calculations.

Step 2: Calculate Pipe Area (\(A\))

Next, we calculate the cross-sectional area of the pipe using our converted diameter.

The area of the 6-inch pipe is 0.1963 square feet.

Step 3: Calculate Velocity (\(V\))

Finally, we find the velocity by dividing the flow rate (in cfs) by the pipe area (in ft²).

The resulting velocity is 5.675 ft/s. We will round this to 5.68 ft/s for the next steps.

Schematic (After Calculations)

Calculated Velocity

Analysis

The water will move through the 6-inch pipe at approximately 5.7 feet per second. This is a typical velocity for water distribution systems, which often operate between 3 and 10 ft/s.

Cautionary Points

Do not confuse GPM (Gallons Per Minute) with cfs (cubic feet per second). All energy equations (like Darcy-Weisbach) require units of feet and seconds. All calculations will be wrong if you use GPM or inches directly.

Key Takeaways

- Continuity Equation: \(V = Q/A\).

- Key Conversions: 6 in = 0.5 ft, 500 GPM = 1.114 cfs.

- Pipe Area: \(A = \pi D^2 / 4\).

Did You Know?

A US gallon (231 in³) is different from an Imperial gallon (277.4 in³) used in the UK. This is why using standard, non-ambiguous units like ft³/s (cfs) or m³/s is essential in international engineering.

FAQ

[List common follow-up questions students might have.]

Final Result

Your Turn

What would the velocity be if the flow rate was 600 GPM?

Memo Card

Question 1 Summary:

- Key Concept: \(V = Q/A\)

- Essential Formula: \(V = \frac{Q_{\text{GPM}} \times 0.002228}{\pi (D_{\text{in}}/12)^2 / 4}\)

- Key Data: \(Q=500\) GPM, \(D=6\) in

Question 2: Calculate the major (friction) head loss (\(h_f\)).

Principle

We use the Darcy-Weisbach equation to find the energy lost to friction along the 800-foot length of pipe. This loss is proportional to the friction factor (\(f\)), the pipe length (\(L\)), the diameter (\(D\)), and the velocity head (\(V^2/2g\)).

Mini-Lesson

The Darcy-Weisbach equation is the standard for calculating friction loss in fully developed, incompressible flow. The friction factor \(f\) accounts for the pipe's relative roughness (\(\epsilon/D\)) and the Reynolds number (Re). In this problem, \(f\) is given, but it is typically found using a Moody Diagram.

Pedagogical Note

Notice that friction loss \(h_f\) is proportional to \(L\) (a longer pipe has more loss) and \(V^2\) (loss increases exponentially with velocity). It is *inversely* proportional to \(D\), so a larger pipe significantly reduces friction loss.

Norms

The Darcy-Weisbach equation is a fundamental principle of fluid dynamics. The methods for finding the friction factor \(f\) are standardized, such as through the Colebrook-White equation, which is the basis for the Moody Diagram (ASCE/AWWA standards).

Formula(s)

Velocity Head

Darcy-Weisbach Equation

Hypotheses

We assume steady, incompressible, and fully developed turbulent flow. We also assume the given friction factor \(f = 0.020\) is constant and correct for this flow regime.

Data

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Friction Factor | \(f\) | 0.020 | - |

| Pipe Length | \(L\) | 800 | ft |

| Pipe Diameter | \(D\) | 0.5 | ft |

| Velocity (from Q1) | \(V\) | 5.68 | ft/s |

| Gravity | \(g\) | 32.2 | ft/s² |

Tips

The most common error is a unit mismatch. Ensure \(L\) and \(D\) are both in feet. Since \(V^2/2g\) (velocity head) is a common term, it's often best to calculate it first, as we did in Q1.

Schematic (Before Calculations)

Friction Loss (\(h_f\))

Calculation(s)

Step 1: Calculate Velocity Head (\(V^2/2g\))

This term represents the kinetic energy of the fluid. We use the velocity \(V = 5.68\) ft/s from Question 1.

The velocity head is 0.501 ft. This value will be used for all friction and minor loss calculations.

Step 2: Calculate Friction Loss (\(h_f\))

Now, we substitute all our known values into the Darcy-Weisbach equation: \(f=0.020\), \(L=800\) ft, \(D=0.5\) ft, and the velocity head we just calculated.

The total energy lost to friction along the 800-ft pipe is 16.03 ft of head.

Schematic (After Calculations)

Energy Grade Line (EGL) Drop due to Friction

Analysis

The friction in the 800-ft pipe causes an energy loss equivalent to 16.03 feet of head. This is the main contributor to the "dynamic" losses in the system.

Cautionary Points

Be careful not to confuse the Darcy-Weisbach friction factor (\(f\)), which is standard in US civil engineering, with the Fanning friction factor (\(f_F\)), which is 1/4 of the Darcy factor and often used in chemical engineering.

Key Takeaways

- Major loss is a function of \(L\), \(D\), \(f\), and \(V^2\).

- This is almost always the most significant head loss component in long pipe systems.

Did You Know?

The Colebrook-White equation is an implicit equation (it must be solved iteratively) that is used to find the friction factor \(f\) for all flow regimes. The Moody Diagram is simply a graphical solution to this complex equation.

FAQ

[List common follow-up questions students might have.]

Final Result

Your Turn

What would \(h_f\) be if a rougher pipe with \(f = 0.025\) was used?

Memo Card

Question 2 Summary:

- Key Concept: Darcy-Weisbach Equation

- Essential Formula: \(h_f = f(L/D)(V^2/2g)\)

- Key Data: \(f=0.020\), \(L=800\), \(D=0.5\), \(V^2/2g=0.501\)

Question 3: Calculate the total minor head loss (\(h_m\)).

Principle

Minor losses are caused by turbulence at fittings, valves, and transitions (like the pipe entrance and exit). We calculate them by summing all the individual loss coefficients (\(K\)) and multiplying by the velocity head (\(V^2/2g\)).

Mini-Lesson

Each fitting that disrupts smooth flow (like an elbow, valve, or change in area) has a loss coefficient \(K\). This \(K\)-factor is determined experimentally and represents the number of velocity heads lost at that component. To get the total minor loss, we simply add all the K-factors in the system and multiply by the velocity head.

Pedagogical Note

While called "minor," these losses can be very significant in systems with many fittings (like in a building's mechanical room). In long, straight pipelines (like this exercise), they are typically much smaller than the "major" friction losses.

Norms

K-factors are not derived from theory but are empirical values published in engineering handbooks and technical papers, such as the Crane Technical Paper No. 410, which is a standard reference in US fluid engineering.

Formula(s)

Total Loss Coefficient

Minor Loss Equation

Hypotheses

We assume the published K-factors are accurate for the specific components used and that they do not change with flow velocity (which is a common simplification).

Data

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| K (Entrance) | \(K_{\text{ent}}\) | 0.5 | - |

| K (Elbows, total) | \(\Sigma K_{\text{elb}}\) | 0.6 | - |

| K (Check Valve) | \(K_{\text{val}}\) | 2.0 | - |

| K (Exit) | \(K_{\text{exit}}\) | 1.0 | - |

| Velocity Head (from Q2) | \(V^2/2g\) | 0.501 | ft |

Tips

A common mistake is forgetting the entrance and exit losses! Every system has at least these two. A pipe pulling from a reservoir always has an entrance loss (\(K \approx 0.5\) for sharp-edged), and a pipe discharging into a reservoir *always* has an exit loss of \(K = 1.0\).

Schematic (Before Calculations)

Minor Losses (\(h_m\))

Calculation(s)

Step 1: Sum Loss Coefficients (\(\Sigma K\))

We sum all the K-factors listed in the problem data table (entrance, elbows, valve, and exit).

The total loss coefficient for all fittings is 4.1 (dimensionless).

Step 2: Calculate Minor Loss (\(h_m\))

We multiply this total K-factor by the velocity head we calculated in Question 2 (\(V^2/2g = 0.501\) ft).

The total energy lost to turbulence in the fittings is 2.054 ft. We will round this to 2.05 ft.

Schematic (After Calculations)

Loss Comparison

Analysis

The total minor loss is 2.05 ft. As expected in this long pipe system, this is much smaller than the major loss (16.03 ft). The minor losses only account for about 11% of the total head loss.

Cautionary Points

Always double-check the K-factors. Are the elbows 90° or 45°? Is the valve a globe valve (\(K \approx 10\)) or a gate valve (\(K \approx 0.2\))? The check valve (\(K=2.0\)) is the largest minor loss contributor here.

Key Takeaways

- Minor losses are calculated by summing K-factors.

- Entrance (\(K \approx 0.5\)) and Exit (\(K = 1.0\)) losses are almost always present.

Did You Know?

An alternative method for minor losses is the Equivalent Length (L/D) method, where each fitting is represented as an "equivalent length" of straight pipe that would produce the same friction loss.

FAQ

[List common follow-up questions students might have.]

Final Result

Your Turn

What would \(h_m\) be if the check valve was removed (\(K_{\text{val}} = 0\))?

Memo Card

Question 3 Summary:

- Key Concept: Minor Loss Calculation

- Essential Formula: \(h_m = (\Sigma K)(V^2/2g)\)

- Key Data: \(\Sigma K = 4.1\), \(V^2/2g=0.501\) ft

Question 4: Calculate the total system head (required pump head, \(H_p\)).

Principle

The total head the pump must provide (\(H_p\)) is the sum of the static head (the elevation change) and all the head losses (major and minor) that it must overcome to maintain the 500 GPM flow.

Mini-Lesson

The simplified energy equation is \(H_p = (z_B - z_A) + h_{L,total}\).

- \((z_B - z_A)\) is the Static Head: the physical height difference, which is constant.

- \(h_{L,total} = h_f + h_m\) is the Dynamic Head: the friction and minor losses, which depend on \(\mathbf{V^2}\) (and thus on \(Q^2\)).

Pedagogical Note

Think of it this way: the pump must first lift the water 120 ft (static head). Then, it must provide an *additional* 18.08 ft of head (dynamic head) just to overcome system friction and keep the water moving at 500 GPM.

Norms

This application of the general energy equation is a fundamental principle of hydraulics, forming the basis for all pump selection and system design.

Formula(s)

Static Head

Total Head Loss

Total Pump Head (System Head)

Hypotheses

We assume the elevations of the reservoirs (\(z_A\) and \(z_B\)) are constant and do not change as water is pumped.

Data

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Reservoir A Elevation | \(z_A\) | 100 | ft |

| Reservoir B Elevation | \(z_B\) | 220 | ft |

| Friction Loss (from Q2) | \(h_f\) | 16.03 | ft |

| Minor Loss (from Q3) | \(h_m\) | 2.05 | ft |

Tips

Always draw the Energy Grade Line (EGL) and Hydraulic Grade Line (HGL). The EGL shows the total head. It starts at \(z_A\), jumps up by \(H_p\) at the pump, and then slopes downward (due to \(h_f\) and \(h_m\)) until it reaches \(z_B\).

Schematic (After Calculations)

Energy Grade Line (EGL)

Calculation(s)

Step 1: Calculate Static Head (\(H_{\text{static}}\))

This is the physical elevation difference between the discharge (Reservoir B) and suction (Reservoir A) surfaces.

The pump must lift the water 120 ft, even if there were no flow or friction.

Step 2: Calculate Total Head Loss (\(h_{L, \text{total}}\))

This is the sum of the major (friction) loss from Q2 and the minor loss from Q3.

The pump must provide an additional 18.08 ft of head just to overcome all the system's "dynamic" resistance.

Step 3: Calculate Total Pump Head (\(H_p\))

The total head required from the pump is the sum of the static lift (Step 1) and the total dynamic losses (Step 2).

This is the final required system head: 138.08 ft.

Analysis

The pump must provide 138.08 feet of head (energy) to lift the water 120 feet vertically *and* overcome the 18.08 feet of energy lost to friction and turbulence, all while maintaining a flow of 500 GPM. This is the "system head" at 500 GPM.

Cautionary Points

A common mistake is forgetting the head losses (\(h_L\)). A pump selected only for the 120 ft static head would fail to deliver the required 500 GPM.

Key Takeaways

- System Head = Static Head + Dynamic Head (Total Losses).

- Static head is constant, but dynamic head changes with \(Q^2\).

Did You Know?

A plot of \(H_p\) vs. \(Q\) (like the one in the simulator) is called the System Curve. To select a pump, you plot this System Curve on top of a manufacturer's Pump Curve. The point where they intersect is the Operating Point.

FAQ

[List common follow-up questions students might have.]

Final Result

Your Turn

What is the required \(H_p\) if the upper reservoir (\(z_B\)) is raised to 250 ft?

Memo Card

Question 4 Summary:

- Key Concept: System Head

- Essential Formula: \(H_p = (z_B - z_A) + h_f + h_m\)

- Key Data: \(H_{\text{static}}=120\) ft, \(h_{L, \text{total}}=18.08\) ft

Question 5: Calculate the required Brake Horsepower (BHP) for the pump.

Principle

Brake Horsepower (BHP) is the actual power required at the pump shaft. It is calculated from the Water Horsepower (WHP) — the power delivered to the fluid — divided by the pump's efficiency (\(\eta\)) to account for energy lost within the pump itself.

Mini-Lesson

Water Horsepower (WHP): The power the pump transfers *to the water*. In US units, \(WHP = (Q_{GPM} \times H_p) / 3960\).

Brake Horsepower (BHP): The power the motor must supply *to the pump's shaft*. Since pumps are not 100% efficient (due to internal friction, turbulence, etc.), the BHP is always higher than the WHP.

Pedagogical Note

The \(\eta = 0.75\) means 75% of the shaft power (BHP) becomes useful water power (WHP). The other 25% is lost, mostly as heat, inside the pump housing.

Norms

Pumps and motors are sold in standard sizes (e.g., 10, 15, 20, 25 HP). After calculating the required BHP (e.g., 23.24 HP), engineers must select the next *standard size up* (e.g., 25 HP) to ensure the motor is not overloaded. These sizes are standardized by NEMA (National Electrical Manufacturers Association).

Formula(s)

Water Horsepower (WHP) (US Customary)

Brake Horsepower (BHP)

Hypotheses

We assume the given pump efficiency (\(\eta = 75\%\)) is the "Best Efficiency Point" (BEP) and that our operating point (500 GPM @ 138.08 ft) is at or near this BEP.

Data

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Flow Rate | \(Q\) | 500 | GPM |

| Total Pump Head (from Q4) | \(H_p\) | 138.08 | ft |

| Pump Efficiency | \(\eta\) | 0.75 | (75%) |

Tips

The constant 3960 is a conversion factor specific to US Customary units (GPM and feet). Ensure efficiency (\(\eta\)) is used as a decimal (e.g., 75% = 0.75).

Schematic (Before Calculations)

Power Flow

Calculation(s)

Step 1: Calculate Water Horsepower (WHP)

We use the formula for WHP, substituting our flow rate \(Q = 500\) GPM and the total head \(H_p = 138.08\) ft from Q4.

The power successfully transferred to the water is 17.43 HP.

Step 2: Calculate Brake Horsepower (BHP)

To find the *actual* power required at the shaft, we divide the WHP by the pump's efficiency (\(\eta = 75\% = 0.75\)).

The pump will require a motor capable of delivering 23.24 HP to its shaft.

Schematic (After Calculations)

Power Conversion (Sankey Diagram)

Analysis

The pump requires 23.24 HP from its motor. Based on this, a standard 25 HP motor would be selected for this application, providing a safe margin.

Cautionary Points

Do not confuse pump efficiency (\(\eta_{\text{pump}}\)) with motor efficiency (\(\eta_{\text{motor}}\)). The total power drawn from the electrical grid (the "Wire Horsepower") would be \(BHP / \eta_{\text{motor}}\). A 25 HP motor might be 90% efficient, drawing \(23.24 / 0.90 \approx 25.8\) HP (or 19.2 kW) of electricity.

Key Takeaways

- Brake Horsepower (BHP) is the shaft power required by the pump.

- Water Horsepower (WHP) is the power delivered to the water.

- \(BHP = WHP / \eta\). BHP is always greater than WHP.

Did You Know?

The "Affinity Laws" are a set of rules that predict how a pump's head (\(H\)), flow (\(Q\)), and power (BHP) change if its rotational speed (RPM) or impeller diameter changes. For example, flow (\(Q\)) is directly proportional to speed (RPM), but power (BHP) is proportional to the *cube* of the speed (\(RPM^3\))!

FAQ

[List common follow-up questions students might have.]

Final Result

Your Turn

What is the required BHP if a less efficient pump (\(\eta = 65\%\)) is used?

Memo Card

Question 5 Summary:

- Key Concept: Pump Power Calculation

- Essential Formula: \(BHP = \frac{Q_{\text{GPM}} \times H_p}{3960 \times \eta}\)

- Key Data: \(Q=500\), \(H_p=138.08\), \(\eta=0.75\)

Interactive Tool: System Head Curve Calculator

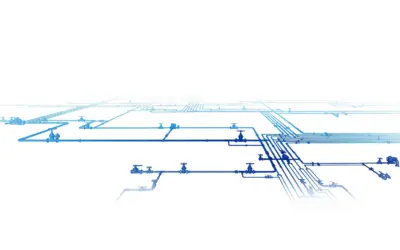

Use the sliders to see how Flow Rate and Pipe Diameter affect the Total System Head. Notice that head loss is highly dependent on flow (it increases with \(Q^2\)). This plotted line is the System Curve.

Input Parameters

Key Requirements (at selected Q)

Final Quiz: Test Your Knowledge

1. In a pumping system, what does "Static Head" represent?

2. If you *increase* the pipe diameter (while flow rate remains the same), what happens to the friction head loss (\(h_f\))?

3. The Darcy-Weisbach equation is used to calculate:

Glossary

- Brake Horsepower (BHP)

- The actual power required at the pump shaft, as supplied by a motor. It accounts for the pump's inefficiency. \(BHP = WHP / \eta\).

- Darcy-Weisbach Equation

- A complex but accurate equation used to calculate major head losses (friction) in a pipe: \(h_f = f(L/D)(V^2/2g)\).

- Head (Hydraulic)

- A measure of the total energy of a fluid at a certain point, expressed in units of height (e.g., feet). It includes elevation head (\(z\)), pressure head (\(p/\gamma\)), and velocity head (\(V^2/2g\)).

- Minor Losses (\(h_m\))

- Energy losses caused by turbulence at components like valves, bends, and pipe transitions. Calculated using \(h_m = (\Sigma K)(V^2/2g)\).

- Static Head (\(H_{\text{static}}\))

- The simple vertical difference in elevation between the source (suction) and destination (discharge) water surfaces. In this exercise, \(H_{\text{static}} = z_B - z_A\).

- System Head (\(H_p\))

- The total head the pump must generate at a given flow rate. It is the sum of the static head and all head losses. \(H_p = H_{\text{static}} + h_f + h_m\).

- Water Horsepower (WHP)

- The theoretical power delivered by the pump directly to the fluid. \(WHP = (Q \times H_p) / 3960\) in US customary units.

0 Comments