Hydraulic Pump Power Calculation

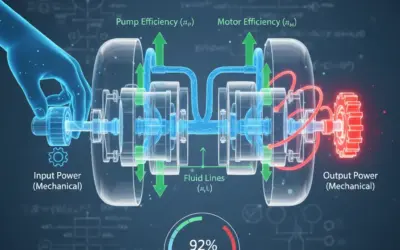

Context: Hydraulic PowerAn engineering field that uses pressurized fluid (usually oil) to transmit energy and control motion. (Fluid Power).

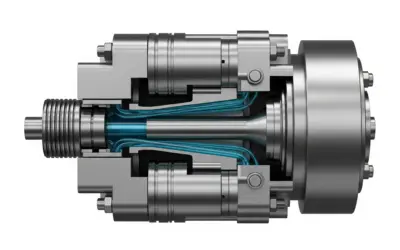

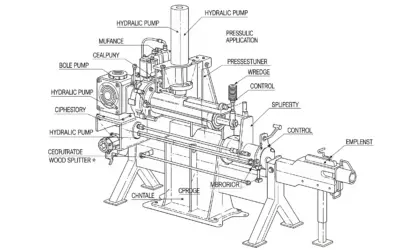

This exercise focuses on the heart of a hydraulic system: the pump. We will analyze a common gear pump to determine its key performance metrics. Using its technical specifications (displacement, speed) and its efficiencies, we will calculate the actual flow rate it delivers, the hydraulic power it transmits to the fluid, and the mechanical power it must draw from the motor to operate.

Learning Note: This exercise will teach you how to calculate the actual flow rate, the hydraulic power delivered, and the mechanical power absorbed by a pump, taking into account its volumetric and mechanical efficiencies.

Learning Objectives

- Calculate the actual flow rate (in GPM) of a pump from its displacement and speed.

- Determine the hydraulic power (in HP) delivered to the fluid.

- Understand and calculate the pump's overall efficiency.

- Calculate the required mechanical input power (in HP) at the drive shaft.

- Determine the torque (in lb-ft) required to drive the pump.

Study Data: Gear Pump

Technical Specs

This table is not used for this exercise.

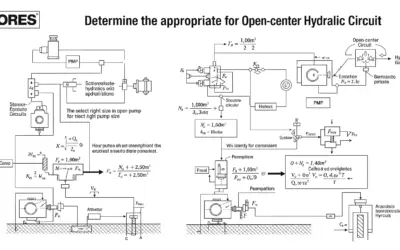

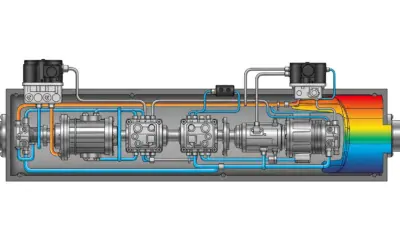

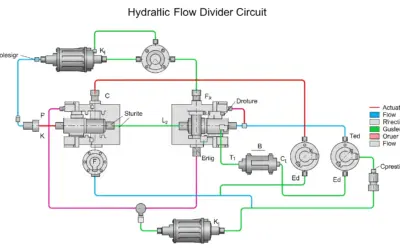

Hydraulic System Schematic

| [Parameter Name] | [Symbol] | [Value] | [Unit] |

|---|---|---|---|

| Geometric Displacement | \(V_g\) | 1.5 | in³/rev |

| Rotational Speed | \(n\) | 1800 | RPM |

| Operating Pressure (Δp) | \(p\) | 3000 | PSI |

| Volumetric Efficiency | \(\eta_v\) | 0.90 | - |

| Mechanical Efficiency | \(\eta_m\) | 0.85 | - |

Questions to Solve

- Calculate the actual flow rate (\(Q\)) of the pump in GPM (US Gallons Per Minute).

- Calculate the hydraulic power (\(P_h\)) delivered to the fluid in HP (Horsepower).

- Calculate the overall efficiency (\(\eta_t\)) of the pump.

- Calculate the mechanical power (\(P_m\)) absorbed by the pump in HP.

- Calculate the torque (\(T\)) required on the pump shaft in lb-ft (Pound-feet).

Fluid Power Fundamentals

To solve this exercise, it's essential to understand the relationships between flow, pressure, speed, and efficiency in a pump.

1. Flow Rate (Q)

Theoretical flow (\(Q_{th}\)) is the volume displaced per revolution multiplied by the speed. Actual flow (\(Q\)) accounts for internal leakage, quantified by volumetric efficiency (\(\eta_v\)).

A key US conversion is \(1 \text{ US Gallon} = 231 \text{ in³}\).

\[ Q \text{ (GPM)} = \frac{V_g \text{ (in³/rev)} \cdot n \text{ (RPM)} \cdot \eta_v}{231} \]

2. Hydraulic Power (\(P_h\))

This is the power transferred to the fluid. It's the product of flow rate and pressure. A common US shortcut gives Horsepower (HP) from GPM and PSI.

\[ P_h \text{ (HP)} = \frac{Q \text{ (GPM)} \cdot p \text{ (PSI)}}{1714} \]

3. Mechanical Power (\(P_m\)) and Efficiencies

Mechanical power is the power absorbed by the pump shaft. It's higher than hydraulic power due to losses (friction, leakage).

\[ \eta_t = \eta_v \cdot \eta_m \]

\[ P_h = P_m \cdot \eta_t \quad \Rightarrow \quad P_m = \frac{P_h}{\eta_t} \]

Mechanical power is also related to torque (\(T\)) and speed (\(n\)).

\[ P_m \text{ (HP)} = \frac{T \text{ (lb-ft)} \cdot n \text{ (RPM)}}{5252} \]

Solution: Hydraulic Pump Power Calculation

Question 1: Calculate the actual flow rate (\(Q\)) in GPM.

Principle

The actual flow rate is the theoretical flow (what the pump should ideally deliver based on its geometry and speed) minus leakage losses. These losses are quantified by the volumetric efficiency. An efficiency of 0.90 means that 90% of the theoretical flow is actually delivered.

Mini-Course

The displacement (\(V_g\)) in in³/rev tells us how many cubic inches of oil are moved per revolution. Multiplying by the speed (\(n\)) in RPM gives the theoretical flow in in³/min. Applying the volumetric efficiency (\(\eta_v\)) gives the actual flow (\(Q\)) in in³/min. Finally, we convert to GPM.

Pedagogical Note

The first step in nearly any hydraulic pump calculation is to find the flow rate. Pay close attention to units: displacement is in in³/rev, speed in RPM, and the final flow is required in GPM. The conversion is essential.

Standards

The formulas used are standard in US fluid power engineering. The conversion \(1 \text{ US Gallon} = 231 \text{ cubic inches}\) is a defined standard.

Formula(s)

The main formula for actual flow is:

And the conversion to GPM:

Assumptions

We assume the given efficiency values are valid for the specified operating conditions (pressure and speed). In reality, efficiencies vary with pressure, speed, and fluid viscosity.

Given Data

The relevant data for this question:

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Geometric Displacement | \(V_g\) | 1.5 | in³/rev |

| Rotational Speed | \(n\) | 1800 | RPM |

| Volumetric Efficiency | \(\eta_v\) | 0.90 | - |

Tips & Tricks

The conversion \(1 \text{ GPM} = 231 \text{ in³/min}\) is fundamental in US hydraulics. You can combine the formulas: \(Q \text{ (GPM)} = (V_g \times n \times \eta_v) / 231\). This is a common shortcut.

Diagram (Before Calculation)

The schematic shows the pump (P) driven by the shaft (\(n\)) and producing a flow (\(Q\)) at the outlet.

Flow Rate Visualization

Calculation(s)

We will break down the calculation step-by-step, substituting symbols with their values.

Step 1: Calculate theoretical flow (before losses)

We multiply the displacement (volume per rev) by the speed (revs per minute) to get a volume per minute.

The result of this first step is the *ideal* (theoretical) flow of 2700 cubic inches per minute.

Step 2: Calculate actual flow (with losses)

We apply the volumetric efficiency (\(\eta_v\)) to the theoretical flow to find the actual flow leaving the pump. This is 90% of the theoretical flow.

After applying the 0.90 (90%) efficiency, the actual flow rate is 2430 in³/min, accounting for internal leakage.

Step 3: Convert to GPM

We convert in³/min to GPM, knowing that \(1 \text{ US Gallon} = 231 \text{ in³}\). We must divide our result by 231.

The final conversion gives us the pump's actual flow rate in US Gallons Per Minute, which is the value requested for this question.

Diagram (After Calculation)

We now have a numerical value for \(Q\) at the pump's outlet.

Flow Rate Result

Analysis

A flow rate of 10.52 GPM is a typical value for a pump of this size in a mobile or light industrial application. If we hadn't accounted for efficiency, the theoretical flow would have been \(2700 / 231 = 11.69 \text{ GPM}\). The difference (about 1.17 GPM) is the internal leakage that returns to the inlet.

Key Warnings

The most common error is forgetting the \( \text{in³} \rightarrow \text{GPM} \) conversion (dividing by 231). Finding a flow of 2430 GPM would be an incoherent order of magnitude for this application.

Key Takeaways

- The key formula is \(Q = V_g \cdot n \cdot \eta_v\).

- Volumetric efficiency always reduces the theoretical flow.

- The conversion \(1 \text{ GPM} = 231 \text{ in³}\) is fundamental.

Did You Know?

In piston pumps, volumetric efficiency is often very high (over 0.95 or 95%), as leakage is better controlled than in a gear pump, where the clearance between the gear teeth and the housing is a more significant source of leakage.

FAQ

Common questions about this calculation:

Final Result

Try It Yourself

Recalculate the actual flow \(Q\) (in GPM) if the displacement was \(V_g = 1.8 \text{ in³/rev}\) (all other parameters unchanged).

Quick Memo

Question 1 Summary:

- Key Concept: Actual Flow = Theoretical Flow × Volumetric Efficiency.

- Key Formula: \(Q \text{ (GPM)} = (V_g \cdot n \cdot \eta_v) / 231\).

Question 2: Calculate the hydraulic power (\(P_h\)) in HP.

Principle

Hydraulic power is the energy transferred to the fluid per unit of time. It is the product of the flow rate (\(Q\)) which "pushes" and the pressure (\(p\)) which "resists". This is the actual useful power of the system.

Mini-Course

The basic formula for power is \(P = \text{Force} \times \text{Velocity}\). In hydraulics, this translates to \(P = (p \times A) \times v\), where A is the area and v is the fluid velocity. Since \(Q = A \times v\), we get \(P_h = p \cdot Q\). For the units to be consistent for Horsepower, we must use specific conversions.

Pedagogical Note

Unit conversion is the trickiest part here. Professionals use "shortcut" formulas that embed the conversions. We will show both methods: the rigorous SI method (which is rare in the US) and the "shortcut" method (common practice).

Standards

The use of Horsepower (HP), PSI, and GPM are standard in the US fluid power industry (SAE standards).

Formula(s)

"Shortcut" Formula (US Customary Units):

Rigorous Formula (SI Units):

Assumptions

We assume the pressure \(p\) of 3000 PSI is the net pressure difference across the pump (outlet pressure minus inlet pressure). The inlet pressure is often neglected (assumed to be 0 PSI gauge).

Given Data

The relevant data for this question:

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Actual Flow (from Q1) | \(Q\) | 10.52 | GPM |

| Operating Pressure | \(p\) | 3000 | PSI |

Tips & Tricks

Why 1714? It's the "magic number" for US hydraulics.

\(1 \text{ HP} = 550 \text{ ft-lb/s}\)

\(1 \text{ GPM} = 0.002228 \text{ ft³/s}\)

\(1 \text{ PSI} = 144 \text{ lb/ft²}\)

\(P \text{ (ft-lb/s)} = Q \text{ (ft³/s)} \times p \text{ (lb/ft²)} \)

\(P \text{ (HP)} = (Q_{\text{gpm}} \times 0.002228) \times (p_{\text{psi}} \times 144) / 550 \)

\(P \text{ (HP)} = (Q \times p) \times (0.002228 \times 144 / 550) \)

\(P \text{ (HP)} = (Q \times p) / (1 / 0.0005834) \approx (Q \times p) / 1714 \)

Knowing where "1714" comes from helps you trust it.

Diagram (Before Calculation)

We are calculating the power at the "Outlet" of the schematic, where flow \(Q\) and pressure \(p\) are at their maximum.

Power = (Pressure × Flow) / 1714

Calculation(s)

We will use the common US shortcut formula.

Method 1: Shortcut (US Customary Units)

We use the formula \(P_h \text{ (HP)} = (Q \cdot p) / 1714\). We substitute \(Q\) with 10.52 GPM and \(p\) with 3000 PSI.

The numerator (31560) is the simple product of the values. The divisor (1714) is the conversion constant (explained in "Tips") that converts (GPM × PSI) directly to Horsepower.

Method 2 (Verification): Rigorous Method

This method shows the calculation using base US units (in, lb, s).

1. Convert flow \(Q\) to in³/s:

2. Calculate power in in-lb/s:

3. Convert in-lb/s to HP (since \(1 \text{ HP} = 550 \text{ ft-lb/s} = 6600 \text{ in-lb/s}\)):

Both methods yield the same result. The "1714" shortcut is just faster.

Diagram (After Calculation)

The useful power transferred to the fluid is 18.41 HP.

Analysis

18.41 HP is a significant amount of power, equivalent to a large riding lawnmower engine. This is the energy available to power the cylinders, motors, and other actuators in the circuit. It is the "useful" power of the system.

Key Warnings

Do not mix units. Only use the "1714" formula if the flow is in GPM and the pressure is in PSI. If you use other units, the constant changes.

Key Takeaways

- Hydraulic power is the product of flow and pressure.

- The formula \(P_h \text{ (HP)} = (Q \cdot p) / 1714\) is an essential shortcut for GPM and PSI.

Did You Know?

The constant "1714" is a famous "mechanic's constant" in US fluid power. Mastering it saves considerable time and avoids conversion errors.

FAQ

...

Final Result

Try It Yourself

Recalculate the hydraulic power \(P_h\) (in HP) if the pressure was 2500 PSI (with the same flow of 10.52 GPM).

Quick Memo

Question 2 Summary:

- Key Concept: Power = Pressure × Flow.

- Key Formula (practical): \(P_h \text{ (HP)} = \frac{Q \text{ (GPM)} \cdot p \text{ (PSI)}}{1714}\).

Question 3: Calculate the overall efficiency (\(\eta_t\)) of the pump.

Principle

The overall efficiency (\(\eta_t\)) is not a new source of loss, but simply the combination of all losses. It represents the pump's total effectiveness at converting mechanical shaft power into hydraulic fluid power.

Mini-Course

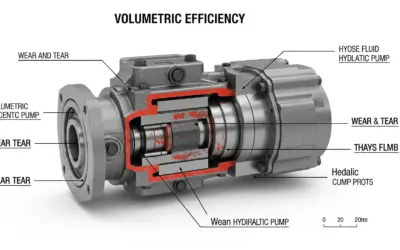

Losses in a pump are of two types:

1. Volumetric Losses (Leakage): Some fluid slips from the outlet back to the inlet. Quantified by \(\eta_v\).

2. Mechanical Losses (Friction): Friction in gears, bearings, seals, etc. This requires "extra" torque to overcome. Quantified by \(\eta_m\).

The overall efficiency is the product of these two efficiencies.

Pedagogical Note

It's important not to add efficiencies! Losses are compounded. If you lose 10% from leakage (\(\eta_v = 0.90\)) and 15% from friction (\(\eta_m = 0.85\)), the total loss is not 10+15=25%. The overall efficiency is \(0.90 \times 0.85 = 0.765\), which is a 23.5% total loss.

Standards

The definition of partial and overall efficiencies is a standard concept in fluid mechanics and engineering.

Formula(s)

Overall Efficiency

Assumptions

We assume the two efficiencies are independent, although in reality they are linked by fluid physics (viscosity, etc.).

Given Data

The relevant data for this question:

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Volumetric Efficiency | \(\eta_v\) | 0.90 | - |

| Mechanical Efficiency | \(\eta_m\) | 0.85 | - |

Tips & Tricks

A good overall efficiency for a gear pump is between 75% and 85%. An efficiency of 90-95% is excellent and typical of piston pumps. If your calculation gives 50% or 110%, there is an error.

Diagram (Before Calculation)

...

Compounding Efficiencies

Calculation(s)

The calculation is a simple multiplication of the two partial efficiencies given in the problem statement.

Step 1: Multiply efficiencies

We substitute \(\eta_v\) with 0.90 (90% volumetric efficiency) and \(\eta_m\) with 0.85 (85% mechanical efficiency).

The overall efficiency is the product of these two values, 0.765, which means 76.5%.

Diagram (After Calculation)

The overall efficiency is a dimensionless value, often expressed as a percentage.

Analysis

An overall efficiency of 0.765 (or 76.5%) means that almost 23.5% of the mechanical energy supplied to the shaft is lost (converted to heat) due to leakage and friction before it can be transmitted to the fluid.

Key Warnings

Never add the efficiencies (\(0.90 + 0.85\)) or the losses (\(10\% + 15\%\)). This is a fundamental error.

Key Takeaways

- Overall efficiency is the product of partial efficiencies: \(\eta_t = \eta_v \cdot \eta_m\).

- It represents the total efficiency of converting mechanical energy to hydraulic energy.

Did You Know?

The lost power (\(P_{lost} = P_m - P_h\)) is almost entirely converted into heat. This is why large hydraulic systems need coolers (heat exchangers) to prevent the oil from overheating.

FAQ

...

Final Result

Try It Yourself

Recalculate the overall efficiency \(\eta_t\) if the mechanical efficiency was better, \(\eta_m = 0.92\) (with \(\eta_v = 0.90\)).

Quick Memo

Question 3 Summary:

- Key Concept: Losses are multiplicative.

- Key Formula: \(\eta_t = \eta_v \cdot \eta_m\).

Question 4: Calculate the mechanical power (\(P_m\)) absorbed by the pump in HP.

Principle

The pump is not perfect (as shown by \(\eta_t\)). To deliver 18.41 HP of *hydraulic* power, it must absorb *more* than 18.41 HP of *mechanical* power from the motor. The mechanical power is the power "paid" to the motor to get the "useful" hydraulic power.

Mini-Course

The very definition of overall efficiency is the ratio of power output (useful) to power input (absorbed).

\[ \eta_t = \frac{P_{\text{output}}}{P_{\text{input}}} = \frac{P_{\text{hydraulic}}}{P_{\text{mechanical}}} \]

By rearranging this formula, we find the input power:

\[ P_{\text{mechanical}} = \frac{P_{\text{hydraulic}}}{\eta_t} \]

Pedagogical Note

Since efficiency (\(\eta_t\)) is a number less than 1, dividing by it will logically increase the value. This is a good sanity check: the absorbed mechanical power (\(P_m\)) must ALWAYS be greater than the delivered hydraulic power (\(P_h\)).

Standards

This is a direct application of the definition of efficiency, a universal concept in engineering.

Formula(s)

Absorbed Mechanical Power

Assumptions

We are using the previously calculated values, assuming they are correct.

Given Data

The relevant data for this question:

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Hydraulic Power (from Q2) | \(P_h\) | 18.41 | HP |

| Overall Efficiency (from Q3) | \(\eta_t\) | 0.765 | - |

Tips & Tricks

To select the drive motor, you must choose a *nominal* power greater than this calculated value (\(P_m\)). An engineer would apply a service factor (e.g., 1.25) and select the next standard motor size up (e.g., 25 HP or 30 HP).

Diagram (Before Calculation)

...

Power Balance

Calculation(s)

We reuse the definition of overall efficiency (\(\eta_t = P_h / P_m\)) which we flip to isolate the mechanical input power (\(P_m\)).

Step 1: Divide by efficiency

We take the useful hydraulic power (\(P_h\)) from Q2 and divide it by the overall efficiency (\(\eta_t\)) from Q3. Dividing by a number < 1 will increase the value, which is logical (input power is greater than output).

The result shows that to *deliver* 18.41 HP to the fluid, the pump must *absorb* 24.07 HP from the motor. We will keep the more precise value (24.065 HP) for the torque calculation in Q5 to avoid rounding errors.

Diagram (After Calculation)

The motor must supply 24.07 HP to the pump shaft.

Analysis

The difference \(P_m - P_h = 24.07 - 18.41 = 5.66 \text{ HP}\) is the "lost" power. This 5.66 HP (over 4.2 kW) is dissipated as heat into the pump body and the oil, which contributes to heating the system.

Key Warnings

Don't reverse the division! If you had calculated \(P_m = P_h \times \eta_t\), you would have found an absorbed power *less* than the delivered power, which is physically impossible (it violates the conservation of energy).

Key Takeaways

- Input power (mechanical) is always greater than output power (hydraulic).

- \(P_{\text{input}} = P_{\text{output}} / \text{Efficiency}\).

Did You Know?

This is the exact same principle for an electric motor's efficiency (electrical power in > mechanical power out) or a combustion engine (chemical power in > mechanical power out).

FAQ

...

Final Result

Try It Yourself

Recalculate the mechanical power \(P_m\) (in HP) if the overall efficiency was better, \(\eta_t = 0.85\) (with \(P_h = 18.41\) HP).

Quick Memo

Question 4 Summary:

- Key Concept: Absorbed Power = Useful Power / Efficiency.

- Key Formula: \(P_m = P_h / \eta_t\).

Question 5: Calculate the torque (\(T\)) on the pump shaft in lb-ft.

Principle

The mechanical power (\(P_m\)) we just calculated is delivered to the pump by a rotating shaft. This power is a combination of two things: the rotational effort (Torque, \(T\)) and the rotational speed (\(n\)). We know the power and the speed, so we can deduce the torque.

Mini-Course

The power of a rotating shaft is \(P_m = T \cdot \omega\).

Torque (\(T\)) is measured in pound-feet (lb-ft).

Angular velocity (\(\omega\)) must be in radians per second (rad/s) for the power to be in ft-lb/s.

A common shortcut in the US is \(P_m \text{ (HP)} = (T \text{ [lb-ft]} \cdot n \text{ [RPM]}) / 5252\).

Pedagogical Note

This is the final step that allows an engineer to size the drive shaft and the coupling between the motor and the pump. Too much torque could shear the shaft. Torque is the "twisting force" the motor must apply.

Standards

The relationship \(P = T \cdot \omega\) is a fundamental formula of Newtonian mechanics. The constant 5252 is a standard conversion factor in US engineering.

Formula(s)

Torque Calculation (US Shortcut)

Conversion from RPM (n) to rad/s (\(\omega\))

Assumptions

We will use the more precise power value \(P_m \approx 24.065 \text{ HP}\) (from \(18.41 / 0.765\)) for better accuracy in the torque calculation, rather than the rounded 24.07 HP.

Given Data

The relevant data for this question:

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Mechanical Power (from Q4) | \(P_m\) | 24.065 | HP |

| Rotational Speed | \(n\) | 1800 | RPM |

Tips & Tricks

Why 5252? It's another "magic number".

\(1 \text{ HP} = 33,000 \text{ ft-lb/min}\).

\(P \text{ (ft-lb/min)} = T \text{ (lb-ft)} \times n \text{ (rev/min)} \times 2\pi \text{ (rad/rev)}\) ... wait, that's not right.

\(P \text{ (ft-lb/min)} = T \text{ (lb-ft)} \times \omega \text{ (rad/min)} \)

\(\omega = n \times 2\pi\). So \(P = T \times n \times 2\pi\).

\(P \text{ (HP)} = (T \times n \times 2\pi) / 33,000 \)

\(P \text{ (HP)} = (T \times n) / (33,000 / 2\pi) \approx (T \times n) / 5252 \).

This shortcut is used everywhere in US automotive and industrial engineering.

Diagram (Before Calculation)

We are calculating \(T\) (Torque, or \(C\) in the French diagram) on the input shaft.

Calculating Shaft Torque

Calculation(s)

We will use the US shortcut formula, as it's the most direct method with HP and RPM.

Step 1: Apply the Torque Shortcut Formula

We rearrange \(P_m = (T \cdot n) / 5252\) to solve for \(T\). We use the unrounded power \(P_m = 24.065 \text{ HP}\) and \(n = 1800 \text{ RPM}\).

The torque required at the shaft is 70.22 lb-ft. This is the rotational effort the motor must provide.

Diagram (After Calculation)

The twisting force on the shaft is 70.22 lb-ft.

Analysis

This torque of 70.22 lb-ft is what the electric motor must constantly provide to turn the pump at 1800 RPM against 3000 PSI of pressure. This is a key value for sizing the shaft coupling.

Key Warnings

The most common error is to forget the 5252 constant, or to mix up units. Only use this formula with HP, lb-ft, and RPM. Using other units (like W or N.m) requires the SI formula \(P = T \cdot \omega\).

Key Takeaways

- Mechanical power links torque and speed: \(P_m = (T \cdot n) / 5252\).

- Torque is calculated as \(T = (P_m \cdot 5252) / n\).

Did You Know?

For a given power level, if the speed (RPM) increases, the required torque decreases (and vice-versa). This is why a Formula 1 engine (very high RPM) has relatively low torque compared to a semi-truck engine (low RPM) for a similar horsepower rating.

FAQ

...

Final Result

Try It Yourself

Recalculate the torque \(T\) (in lb-ft) if the pump ran at 1200 RPM (assuming the same absorbed power \(P_m = 24.065\) HP).

Quick Memo

Question 5 Summary:

- Key Concept: Torque = Power / Angular Speed.

- Key Formula (practical): \(T \text{ (lb-ft)} = \frac{P_m \text{ (HP)} \cdot 5252}{n \text{ (RPM)}}\)

Interactive Tool: Pump Simulator

Use the sliders to see how rotational speed and operating pressure affect the pump's performance (keeping Vg, ηv, and ηm constant).

Input Parameters

Key Results

Final Quiz: Test Your Knowledge

1. What does volumetric efficiency (\(\eta_v\)) quantify?

2. If the operating pressure doubles (at constant flow), how does the hydraulic power change?

3. The standard US unit for pump displacement (\(V_g\)) is:

4. The absorbed mechanical power (\(P_m\)) is always...

5. The formula \(P_h \text{ (HP)} = \frac{Q \text{ (GPM)} \cdot p \text{ (PSI)}}{1714}\) is:

Glossary

- Geometric Displacement (\(V_g\))

- The volume of fluid a pump (theoretically) displaces in one complete revolution of its shaft. Usually in in³/rev or cm³/rev.

- Volumetric Efficiency (\(\eta_v\))

- Ratio of actual flow to theoretical flow (\(Q / Q_{th}\)). It quantifies the pump's effectiveness at moving fluid (losses due to internal leakage).

- Mechanical Efficiency (\(\eta_m\))

- Ratio of theoretical hydraulic power to absorbed mechanical power. It quantifies the pump's effectiveness at overcoming internal friction.

- Overall Efficiency (\(\eta_t\))

- The product of volumetric and mechanical efficiencies (\(\eta_v \times \eta_m\)). It represents the pump's total efficiency.

- PSI (Pounds per Square Inch)

- Common unit of pressure in the US. \(14.5 \text{ PSI} \approx 1 \text{ bar}\).

- GPM (US Gallons Per Minute)

- Common unit of flow rate in the US. \(1 \text{ US Gallon} = 231 \text{ in³} \approx 3.785 \text{ Liters}\).

- Hydraulic Power (\(P_h\))

- Useful power transferred to the fluid, calculated as \(P_h = Q \cdot p\). Measured in Horsepower (HP).

- Mechanical Power (\(P_m\))

- Input power absorbed by the pump's shaft, calculated as \(P_m = T \cdot \omega\). It is always greater than \(P_h\). Measured in Horsepower (HP).

0 Comments