Calculating the Efficiency of a Hydraulic Motor

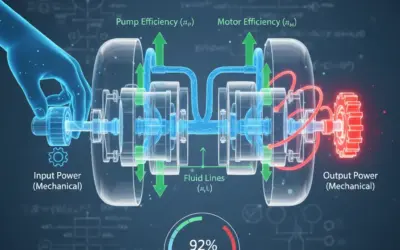

Context: Hydraulic PowerThe field of fluid power that uses mineral or synthetic oils as a fluid to transmit power..

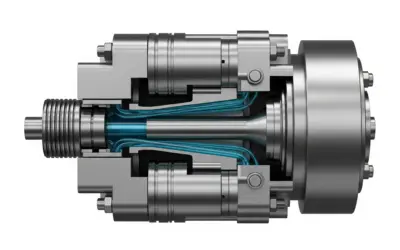

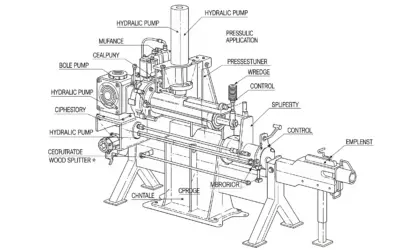

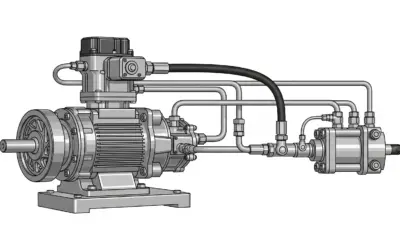

Hydraulic motors are rotary actuators that convert hydraulic power (pressure, flow) into mechanical power (torque, speed). They are essential in many industrial and mobile applications (construction equipment, presses, winches). Understanding their efficiency is crucial for correctly sizing an installation and evaluating its energy performance.

Learning Note: This exercise will teach you to break down the overall efficiency of a hydraulic motor into its two main components: volumetric efficiency (related to leakage) and mechanical efficiency (related to friction).

Learning Objectives

- Calculate volumetric efficiency from speed and flow measurements.

- Calculate mechanical efficiency from torque and pressure measurements.

- Calculate overall efficiency and power loss (dissipated heat).

- Understand the difference between theoretical and actual values.

Problem Data

Technical Specifications

| Characteristic | Value |

|---|---|

| Motor Displacement (\(V_m\)) | 3.0 in³/rev |

| Fluid | ISO VG 46 Hydraulic Oil |

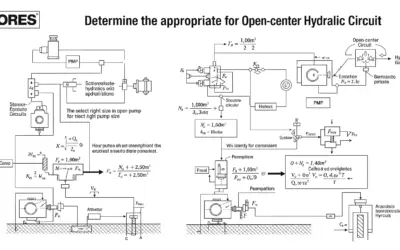

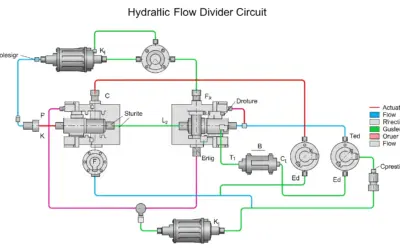

Test Bench Schematic

| Measured Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Actual flow rate into motor | \(Q_{\text{actual}}\) | 15 | gpm |

| Actual shaft speed | \(N_{\text{actual}}\) | 1080 | rpm |

| Pressure differential (inlet - outlet) | \(\Delta P\) | 1750 | psi |

| Actual mechanical torque at shaft | \(C_{\text{actual}}\) | 790 | lb-in |

Questions to Solve

- Calculate the theoretical motor speed \(N_{\text{th}}\) (in rpm).

- Calculate the volumetric efficiency \(\eta_v\) (in %).

- Calculate the theoretical torque \(C_{\text{th}}\) (in lb-in).

- Calculate the mechanical efficiency \(\eta_m\) (in %).

- Calculate the overall efficiency \(\eta_g\) (in %) in two different ways.

Fundamentals of Hydraulic Motors

A hydraulic motor is never perfect. Its efficiency is reduced by two types of losses:

1. Volumetric Losses (Leakage)

Every motor has internal clearances (between pistons and cylinders, etc.). The pressurized fluid "leaks" from the high-pressure side to the low-pressure side without producing work. This means the actual flow rate \(Q_{\text{actual}}\) absorbed is greater than the theoretical flow rate \(Q_{\text{th}}\) that generates the rotation.

\[ Q_{\text{actual}} = Q_{\text{th}} + Q_{\text{leakage}} \]

The volumetric efficiency \(\eta_v\) quantifies this leakage.

2. Mechanical Losses (Friction)

Moving parts (pistons, shaft, bearings) generate friction. The pressure must overcome this friction *before* it can provide useful torque. This means the theoretical torque \(C_{\text{th}}\) generated by the pressure is greater than the actual torque \(C_{\text{actual}}\) available at the shaft.

\[ C_{\text{th}} = C_{\text{actual}} + C_{\text{friction}} \]

The mechanical efficiency \(\eta_m\) quantifies this friction.

Solution: Hydraulic Motor Efficiency Calculation

Question 1: Calculate the theoretical motor speed \(N_{\text{th}}\) (in rpm).

Principle

Theoretical speed is the speed the motor would achieve if there were absolutely no leaks. It's an ideal speed where 100% of the incoming flow (\(Q_{\text{actual}}\)) is converted into rotation, based on the motor's displacement (\(V_m\)).

Mini-Lesson

The displacement \(V_m\) is the volume of fluid the motor absorbs (or displaces) in one revolution. The theoretical flow rate \(Q_{\text{th}}\) is therefore simply this volume per revolution multiplied by the number of revolutions per minute (\(N_{\text{th}}\)). In this question, we reverse this logic: we assume the *actual* flow rate is a *theoretical* flow rate to find the *theoretical* speed.

Learning Note

This is a conceptual trick. We use the actual flow rate (the measured value of 15 gpm) to calculate a theoretical speed. The idea is to see: "if my motor were perfect (no leaks), how fast would it turn with this flow?". Since there will be leaks, we expect the actual speed (\(N_{\text{actual}}\)) to be *lower* than this theoretical speed.

Standards

Efficiency calculations in fluid power are standardized (ISO 4409). Units are crucial: displacements are often in in³/rev, flow rates in gpm, and pressures in psi.

Formula(s)

The basic formula linking flow, displacement, and speed is:

Theoretical Flow

For this question, we rearrange the formula, assuming \(Q_{\text{actual}} = Q_{\text{th}}\) to find \(N_{\text{th}}\):

Assumptions

For this theoretical calculation, we assume a perfect motor:

- Volumetric efficiency \(\eta_v = 1\) (no leaks).

- The actual flow \(Q_{\text{actual}}\) is entirely converted into motion.

Given Data

We need the data from the problem statement for this calculation:

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Actual Flow | \(Q_{\text{actual}}\) | 15 | gpm |

| Displacement | \(V_m\) | 3.0 | in³/rev |

Tips

The crucial point here is unit conversion. We cannot divide gallons by cubic inches. The standard conversion is 1 US Gallon = 231 in³.

Schematic (Before Calculation)

Visualizing the incoming flow and the theoretical rotation.

[Concept: Flow vs. Speed]

Calculation(s)

Step 1: Convert flow \(Q_{\text{actual}}\) to in³/min

The flow's volume unit (gallons) must match the displacement's (in³). We know 1 gal = 231 in³.

Step 2: Calculate theoretical speed \(N_{\text{th}}\)

Now we apply the formula by dividing the flow (in in³/min) by the displacement (in in³/rev). The "in³" units cancel, leaving "rev/min", which is speed (rpm).

Schematic (After Calculation)

Not applicable for this calculation.

Reflection

The theoretical speed is 1155 rpm. The problem gives a measured actual speed of 1080 rpm. It is logical that the actual speed is *lower* than the theoretical speed. The 75 rpm difference is "lost" due to internal leakage.

Points of Caution

The most common error is failing to convert units. Dividing 15 gpm by 3.0 in³/rev would give 5, a physically meaningless result.

Key Takeaways

- Theoretical speed is calculated using the actual input flow.

- \(N_{\text{actual}} < N_{\text{th}}\) because of leakage.

- Unit consistency (gpm to in³/min) is critical.

Did you know?

For a pump, it's the reverse! The theoretical flow (from drive speed) is *less* than the actual flow required to compensate for leaks and build pressure. A pump's volumetric efficiency is calculated differently.

FAQ

Common questions for this step.

Final Result

Now your turn

If the actual flow were 18 gpm (with the same displacement), what would the theoretical speed be?

Memo Card

Question 1 Summary:

- Concept: Ideal speed with no leaks.

- Formula: \(N_{\text{th}} = Q_{\text{actual}} / V_m\).

- Caution: Convert gpm to in³/min (x231).

Question 2: Calculate the volumetric efficiency \(\eta_v\) (in %).

Principle

Volumetric efficiency measures how effectively the motor converts flow into speed. It compares the actual speed (what comes out) to the theoretical speed (what should come out if it were perfect). A 95% efficiency means 5% of the flow is "lost" to internal leakage.

Mini-Lesson

Volumetric efficiency \(\eta_v\) is the ratio of the actual speed \(N_{\text{actual}}\) to the theoretical speed \(N_{\text{th}}\) calculated in the previous question.

It can also be seen as the ratio of the theoretical flow (the flow that creates the actual rotation: \(Q_{\text{th}} = V_m \times N_{\text{actual}}\)) to the actual absorbed flow \(Q_{\text{actual}}\).

Learning Note

Both definitions are equivalent:

\(\eta_v = \frac{N_{\text{actual}}}{N_{\text{th}}}\) (ratio of speeds)

\(\eta_v = \frac{Q_{\text{th}}}{Q_{\text{actual}}} = \frac{V_m \times N_{\text{actual}}}{V_m \times N_{\text{th}}} = \frac{N_{\text{actual}}}{N_{\text{th}}}\)

Using the ratio of speeds is more direct since we just calculated \(N_{\text{th}}\) and \(N_{\text{actual}}\) is given.

Standards

Efficiency is a dimensionless quantity, typically expressed as a percentage (%).

Formula(s)

Formula used for the calculation:

Volumetric Efficiency

Assumptions

We assume the given data (N_actual) and the calculation of N_th are correct.

Given Data

We use the result from Q1 and a value from the problem statement:

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Actual Speed | \(N_{\text{actual}}\) | 1080 | rpm |

| Theoretical Speed (Calc. Q1) | \(N_{\text{th}}\) | 1155 | rpm |

Tips

For the ratio to be correct, both speeds must be in the same unit (here, rpm), which they are. The result will be a number less than 1 (since \(N_{\text{actual}} < N_{\text{th}}\)). Simply multiply by 100 to get a percentage.

Schematic (Before Calculation)

Conceptually, the total flow \(Q_{\text{actual}}\) splits into a leakage flow \(Q_f\) and a "useful" flow \(Q_u\) that generates rotation. \(\eta_v = Q_u / Q_{\text{actual}}\).

[Leakage Concept]

Calculation(s)

Calculate volumetric efficiency \(\eta_v\)

We apply the formula using the actual speed (given) and the theoretical speed (calculated in Q1).

To express this result as a percentage, we multiply by 100.

Schematic (After Calculation)

Not applicable for this calculation.

Reflection

A volumetric efficiency of 93.5% means that 93.5% of the flow absorbed by the motor is useful (generates rotation), and the rest, 100% - 93.5% = 6.5%, is lost in internal leakage (it returns directly to the reservoir without producing work).

Points of Caution

Don't invert the fraction! Efficiency is always less than 1 (or 100%). If you get a result greater than 1 (e.g., 1155 / 1080), you have mixed up \(N_{\text{actual}}\) and \(N_{\text{th}}\).

Key Takeaways

- Volumetric efficiency \(\eta_v\) quantifies leakage losses.

- \(\eta_v = N_{\text{actual}} / N_{\text{th}}\) (always < 1).

Did you know?

This efficiency is not constant. It strongly depends on pressure (as pressure increases, leaks increase, so \(\eta_v\) decreases) and oil viscosity (thicker oil reduces leaks, but increases friction!).

FAQ

Common questions for this step.

Final Result

Now your turn

With the same data (N_th = 1155 rpm), if the measured actual speed was 1100 rpm, what would be the volumetric efficiency?

Memo Card

Question 2 Summary:

- Concept:Efficiency of converting flow to speed.

- Formula: \(\eta_v = N_{\text{actual}} / N_{\text{th}}\).

- Caution: Result < 100%.

Question 3: Calculate the theoretical torque \(C_{\text{th}}\) (in lb-in).

Principle

Theoretical torque is the ideal torque the motor would produce if 100% of the pressure differential (\(\Delta P\)) were converted into rotational effort, with no friction losses. It's the maximum "available" torque from the pressure.

Mini-Lesson

Theoretical torque \(C_{\text{th}}\) is directly proportional to the pressure differential \(\Delta P\) and the displacement \(V_m\). It's the "force" that the pressure exerts on the motor's internal mechanism (pistons) to make it turn. The exact formula includes a \(2\pi\) factor to convert displacement (volume/rev) into torque.

Learning Note

Just like in Q1, we expect the actual torque \(C_{\text{actual}}\) (790 lb-in) to be *lower* than the theoretical torque \(C_{\text{th}}\) we are about to calculate. The difference between them will be the "torque lost" to internal friction.

Standards

To get torque in pound-inches (lb-in), pressure must be in pounds per square inch (psi) and displacement must be in cubic inches per radian (in³/rad). This is a major source of errors.

Formula(s)

The formula is:

Theoretical Torque

Here, \(\Delta P\) is in psi (lb/in²) and \(V_m\) is in in³/rev.

Assumptions

For this calculation, we assume a mechanically perfect motor:

- Mechanical efficiency \(\eta_m = 1\) (no friction).

- The pressure \(\Delta P\) is entirely converted into torque.

Given Data

We need data from the problem statement:

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Pressure Differential | \(\Delta P\) | 1750 | psi |

| Displacement | \(V_m\) | 3.0 | in³/rev |

Tips

The \(2\pi\) is required to convert from "per revolution" (in \(V_m\)) to "per radian," which is the base unit of angle in torque/power equations. The calculation \( ( \text{psi} \times \text{in}^3/\text{rev} ) / (\text{rad}/\text{rev}) \) gives \( (\text{lb}/\text{in}^2 \times \text{in}^3) / \text{rad} = \text{lb-in}/\text{rad} \). This result is torque.

Schematic (Before Calculation)

Modeling the action of pressure \(\Delta P\) on displacement \(V_m\) to generate torque \(C_{\text{th}}\).

[Torque Concept]

Calculation(s)

Calculate theoretical torque \(C_{\text{th}}\)

We apply the formula directly. The units (psi and in³/rev) are standard for this equation.

Schematic (After Calculation)

Not applicable for this calculation.

Reflection

The theoretical torque is 835.5 lb-in. The problem gives a measured actual torque of 790 lb-in. It is logical that the actual torque is *lower* than the theoretical torque. The difference (835.5 - 790 = 45.5 lb-in) is the "torque loss" consumed by the motor's internal friction.

Points of Caution

Forgetting the \(2\pi\) is the most frequent error. Displacement is volume *per revolution*. Torque is force *per radian*. The \(2\pi\) handles the conversion.

Key Takeaways

- Theoretical torque is calculated from the pressure \(\Delta P\).

- \(C_{\text{actual}} < C_{\text{th}}\) because of friction.

- The formula is \(C_{\text{th}} = (\Delta P \times V_m) / 2\pi\).

Did you know?

A motor's "starting torque" is often lower than its running torque, as it must overcome static friction ("stiction"), which is higher than the dynamic (fluid) friction once the motor is spinning.

FAQ

Common questions for this step.

Final Result

Now your turn

If the pressure \(\Delta P\) were 2000 psi (with the same displacement), what would the theoretical torque be?

Memo Card

Question 3 Summary:

- Concept: Ideal torque with no friction.

- Formula: \(C_{\text{th}} = (\Delta P \times V_m) / 2\pi\).

- Caution: Units must be psi and in³/rev.

Question 4: Calculate the mechanical efficiency \(\eta_m\) (in %).

Principle

Mechanical efficiency measures how effectively the motor converts the "pressure force" (theoretical torque) into actual torque at the shaft. It compares the actual torque (what comes out) to the theoretical torque (what should come out if it were perfect). A 90% efficiency means 10% of the torque is "lost" to friction.

Mini-Lesson

Mechanical efficiency \(\eta_m\) is the ratio of the actual torque \(C_{\text{actual}}\) (measured at the shaft) to the theoretical torque \(C_{\text{th}}\) (calculated in Q3). It's the exact mechanical equivalent of volumetric efficiency (which compared speeds).

Learning Note

This efficiency quantifies all friction losses: friction of pistons/vanes, friction in bearings, fluid friction (churning). It is logically always less than 100%.

Standards

Like any efficiency, \(\eta_m\) is a dimensionless number, expressed as a percentage.

Formula(s)

Formula used for the calculation:

Mechanical Efficiency

Assumptions

We assume the given data (C_actual) and the calculation of C_th are correct.

Given Data

We use the result from Q3 and a value from the problem statement:

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Actual Torque | \(C_{\text{actual}}\) | 790 | lb-in |

| Theoretical Torque (Calc. Q3) | \(C_{\text{th}}\) | 835.5 | lb-in |

Tips

Ensure both torques are in the same unit (here, lb-in) before dividing. As with \(\eta_v\), the result must be less than 1.

Schematic (Before Calculation)

Conceptually, the theoretical torque \(C_{\text{th}}\) splits into a torque loss from friction \(C_f\) and a "useful" actual torque \(C_{\text{actual}}\).

[Friction Concept]

Calculation(s)

Calculate mechanical efficiency \(\eta_m\)

We apply the formula using the actual torque (given) and the theoretical torque (calculated in Q3).

To express this result as a percentage, we multiply by 100.

Schematic (After Calculation)

Not applicable for this calculation.

Reflection

A mechanical efficiency of 94.6% (rounded) means that 94.6% of the torque generated by the pressure is transmitted to the shaft, and the remaining 100% - 94.6% = 5.4% is lost to internal friction.

Points of Caution

Don't invert the fraction. Efficiency is always less than 1. \(\eta_m\) is the ratio of what "comes out" (Actual) over what "goes in" (Theoretical).

Key Takeaways

- Mechanical efficiency \(\eta_m\) quantifies friction losses.

- \(\eta_m = C_{\text{actual}} / C_{\text{th}}\) (always < 1).

Did you know?

Mechanical efficiency varies significantly with speed. At very low speeds, static friction is high and \(\eta_m\) is low. At very high speeds, fluid churning (viscous friction) increases, and \(\eta_m\) drops again. It is highest at a nominal "cruise" speed.

FAQ

Common questions for this step.

Final Result

Now your turn

With the same theoretical torque (835.5 lb-in), if the measured actual torque was only 750 lb-in, what would the mechanical efficiency be?

Memo Card

Question 4 Summary:

- Concept: Efficiency of converting pressure to torque.

- Formula: \(\eta_m = C_{\text{actual}} / C_{\text{th}}\).

- Caution: Result < 100%.

Question 5: Calculate the overall efficiency \(\eta_g\) (in %) in two different ways.

Principle

Overall efficiency is the total effectiveness of the motor. It answers the question: "For every 100% of hydraulic power I supply at the inlet, what percentage do I get back as useful mechanical power at the outlet?". This is the most important number for an engineer.

Mini-Lesson

There are two ways to see overall efficiency \(\eta_g\):

1. Product of Efficiencies: The overall efficiency is

simply the product of the volumetric efficiency (flow losses) and the mechanical efficiency (torque losses). \(\eta_g = \eta_v \times \eta_m\).

2. Ratio of Powers: This is the most fundamental definition. \(\eta_g = P_{\text{mechanical}} / P_{\text{hydraulic}}\).

Learning Note

Calculating \(\eta_g\) both ways is an excellent method to check all your calculations. If both methods give the same result, you are (almost) certain you made no mistakes!

Standards

In the US, power is measured in Horsepower (HP). 1 HP \(\approx\) 746 Watts.

Formula(s)

The necessary formulas are:

Method 1: Product of Efficiencies

Method 2: Ratio of Powers

Assumptions

We assume all losses are either volumetric or mechanical. We neglect pure thermal losses (which are, in fact, the result of the first two).

Given Data

We will use all the data from the problem and all previous results.

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Volumetric Efficiency (Q2) | \(\eta_v\) | 0.935 | - |

| Mechanical Efficiency (Q4) | \(\eta_m\) | 0.9455 | - |

| Actual Flow | \(Q_{\text{actual}}\) | 15 | gpm |

| Pressure Differential | \(\Delta P\) | 1750 | psi |

| Actual Torque | \(C_{\text{actual}}\) | 790 | lb-in |

| Actual Speed | \(N_{\text{actual}}\) | 1080 | rpm |

Schematic (Before Calculation)

Power Balance.

[Power Balance]

Points of Caution

Units, units, units! To get Horsepower (HP):

Hydraulic HP = (Flow (gpm) × Pressure (psi)) / 1714

Mechanical HP = (Torque (lb-in) × Speed (rpm)) / 63025

These are the two "magic numbers" for US Customary Units.

Calculation(s) - Method 1

Method 1: Product of Efficiencies

We use the results from Q2 and Q4. This is the fastest method.

Expressed as a percentage:

Calculation(s) - Method 2

Method 2: Ratio of Powers

We must first calculate the hydraulic input power (\(P_h\)) and the mechanical output power (\(P_m\)).

Step 2a: Calculate Hydraulic Power \(P_h\)

We use the "magic number" formula: \(P_h (\text{HP}) = (Q_{\text{actual}} \times \Delta P) / 1714\).

Step 2b: Calculate Mechanical Power \(P_m\)

We use the other "magic number" formula: \(P_m (\text{HP}) = (C_{\text{actual}} \times N_{\text{actual}}) / 63025\).

Step 2c: Calculate Overall Efficiency \(\eta_g\)

We find the ratio of the two powers.

Expressed as a percentage:

Both methods give the same result (88.4%), which validates all our calculations.

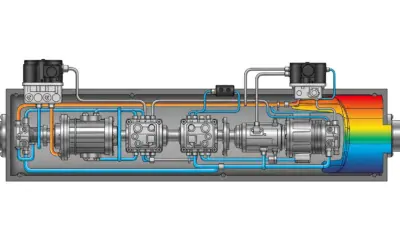

Schematic (After Calculation)

Sankey Diagram (Power Flow & Losses).

[Sankey Diagram]

Reflection

Both methods yield 88.4%. This confirms our calculations. Of the 15.3 HP of hydraulic power supplied to the motor, 13.5 HP is delivered to the shaft, and 1.8 HP is lost (as leakage and friction).

Key Takeaways

- Overall efficiency is the product of the partial efficiencies.

- All losses (leakage, friction) are dissipated almost entirely as heat into the hydraulic fluid.

Did you know?

The lost power (\(P_h - P_m = 1.8 \text{ HP}\)) is converted to heat. 1 HP is ~2544 BTU/hr, so this motor is dumping over 4500 BTU/hr into the oil—like a small space heater! This is why high-power hydraulic systems almost always need an oil cooler.

FAQ

Common questions for this step.

Final Result

Now your turn

What is the total power lost (in HP)? (Hint: It's the difference between \(P_h\) and \(P_m\)).

Memo Card

Question 5 Summary:

- Concept: Total motor efficiency.

- Formulas: \(\eta_g = \eta_v \times \eta_m\) OR \(\eta_g = P_m / P_h\).

- Caution: Power units (HP = gpm * psi / 1714) or (HP = lb-in * rpm / 63025).

Interactive Tool: Efficiency Simulator

Use the sliders to see how pressure and leakage (simulated by a drop in \(\eta_v\)) affect the output power and overall efficiency.

Input Parameters

Key Results

Final Quiz: Test Your Knowledge

1. An actual speed \(N_{\text{actual}}\) that is lower than the theoretical speed \(N_{\text{th}}\) is caused by...

2. An actual torque \(C_{\text{actual}}\) that is lower than the theoretical torque \(C_{\text{th}}\) is caused by...

3. If the pressure \(\Delta P\) increases, what most likely happens?

4. The power lost by the motor (in HP or W) is primarily converted into...

5. Which of these formulas is correct?

Glossary

- Displacement (\(V_m\))

- Volume of fluid absorbed or displaced by the motor (or pump) for one full revolution of its shaft. Unit: in³/rev.

- Volumetric Efficiency (\(\eta_v\))

- Ratio of theoretical flow (needed for the actual speed) to the actual flow consumed. It measures the motor's sealing (leakage).

- Mechanical Efficiency (\(\eta_m\))

- Ratio of actual torque (measured at the shaft) to the theoretical torque generated by the pressure. It measures friction losses.

- Overall Efficiency (\(\eta_g\))

- Ratio of mechanical power output to hydraulic power input. It is the product \(\eta_v \times \eta_m\).

- Fluid Power

- The technology of transmitting power using a pressurized fluid, typically oil (hydraulics) or air (pneumatics).

0 Comments